Stockager® Suite

A complete functional coverage for warehouses of every kind

Increase efficiency, reduce errors, and speed up operations are crucial goals for a modern warehouse. These advantages come from the software's ability to easily integrate with heterogeneous systems and adapt to constantly evolving business needs.

With Stockager® Suite, scalability is a simple and immediate process.

The platform offers complete functional coverage for any type of warehouse, providing support at every stage of logistics. Everything needed to optimize the Warehouse Management of manual, automated, distribution centers (DI.CE.), or mixed-configuration warehouses is available within a single platform.

The main modules of Stockager® Suite

The platform, which can be managed both on-premise and in the cloud, is composed of two main modules:

- StockMan, the Warehouse Management System (WMS). Its flexibility and scalability is ideal to improve efficiency and productivity in every kind every kind of warehouse.

- StockMatic, the Warehouse Control System (WCS) for an integrated management of heterogeneous automatic systems.

Proud to have obtained the validation of Stockager Suite by Warehouse-Logistics.com, the largest online community for selecting IT suppliers for logistics.

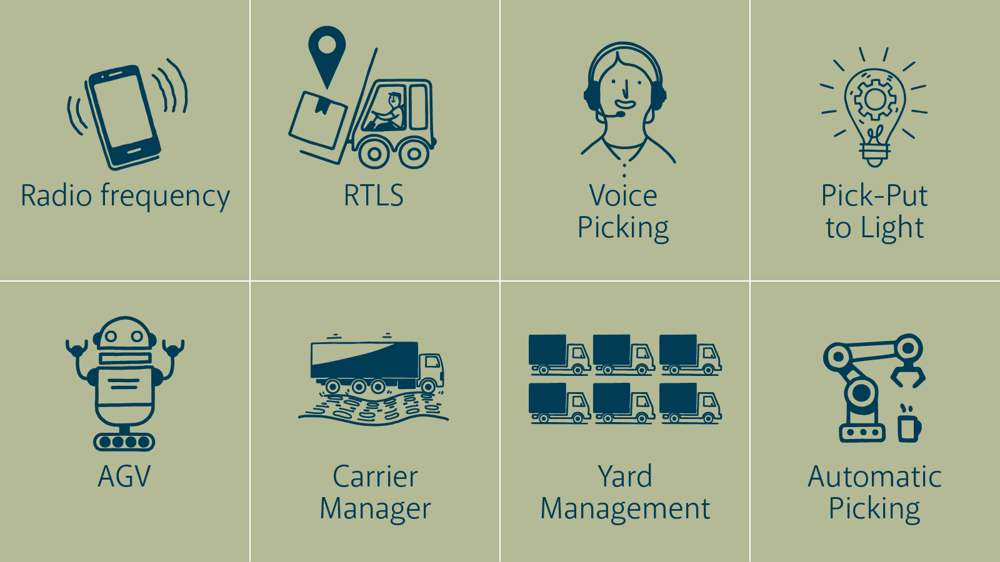

8 add-on modules to meet every need in the warehouse