RTLS

Why you need geolocation systems in the warehouse

The RTLS module uses geolocation technologies that allow the position of each forklift to be monitored at any time. This allows you to memorize the storage coordinates of each pallet, avoiding barcode reading. You can also have constantly updated physical stock and positional data, together with a 3D graphic view of the warehouse map and the entire plant. The result is a warehouses without barcodes, in which pallets and forklifts are located with Cartesian coordinates, and their position is always known, in real time and without additional manual operations.

The advantages of forklifts and trolleys localization

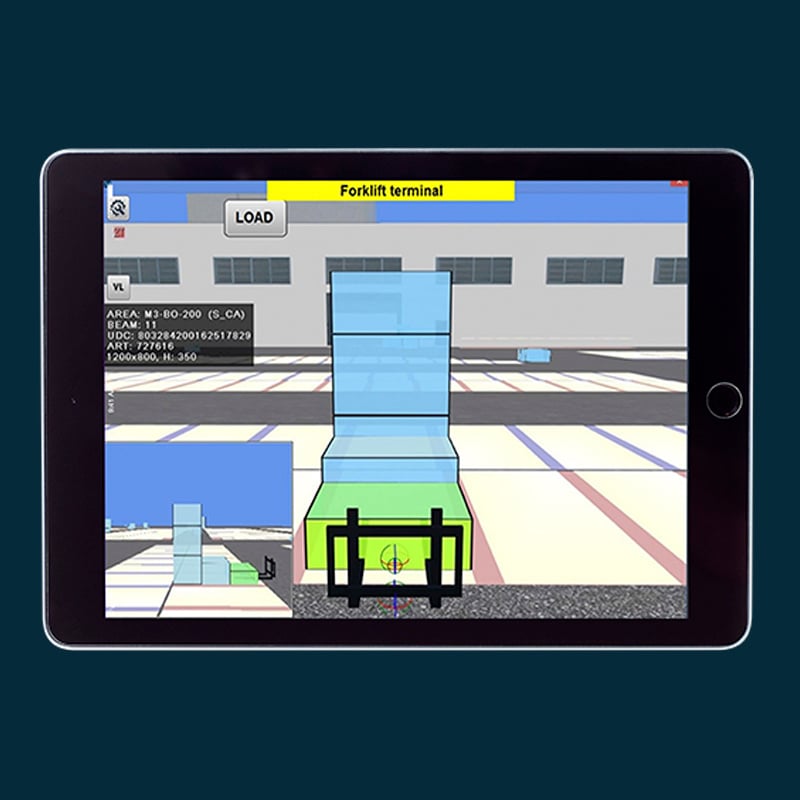

The RTLS module within Stockager® Suite allows you to monitor the position and work of forklift drivers in real time. In this way, forklift drivers receive clear indications, even in 3D graphics, which speed up their missions, eliminating barcode reading time. The system also indicates the route to follow and the exact pallet picking/putting points.

This proves to be very useful for both multi-batch stack management and safety measures, thanks to anti-collision alerts. In addition, onto RTLS equipped carts, a series of tool and devices are installed: XY coordinate calculation devices, fork height sensors (Z coordinate), pallet sensors on the forks, gyroscope (to calculate the forklift rotation angle), and trolley terminal.